Spanning 31,200 square meters, our Xiamen factory is home to 150+ skilled employees and a fully structured organization certified under ISO 9001 standards.

With strong capabilities in industrial design, R&D, and in-house tooling, we offer full control from concept to production. Our exclusive production lines and technical expertise have made Songson a trusted name in the hardware manufacturing industry for over 30 years.

Advanced In-House Production Equipment

Our facility is equipped with a full range of specialized machinery to support complex, high-quality manufacturing — from prototyping to mass production:

12 Hydraulic Deep Drawing Machines

For high-precision metal forming with consistent depth and finish.

9 Pneumatic Press Units

Enabling efficient shaping and assembly for diverse material types.

4 Trimming & Crimping Machines

Ensuring clean edges and structural integrity in final product form.

Water Expansion Machine

Designed for complex shaping and inner-forming of vessels and containers.

Precision Cleaning & Surface Preparation

Cleanliness and surface consistency are critical in premium manufacturing — especially for kitchenware and consumer products. Our facility includes:

2 Ultrasonic Automatic Cleaning Lines

Advanced cleaning systems that use high-frequency vibrations to remove fine particles, oil, and contaminants — ensuring spotless surfaces before assembly or packaging.

2 Automatic Spray Washing Lines

High-efficiency spray lines that deliver uniform surface cleaning and pre-treatment, ideal for achieving consistent coating, bonding, and hygiene standards.

These systems ensure that every product meets strict cleanliness requirements — supporting both aesthetics and safety for food-contact items and high-visibility finishes.

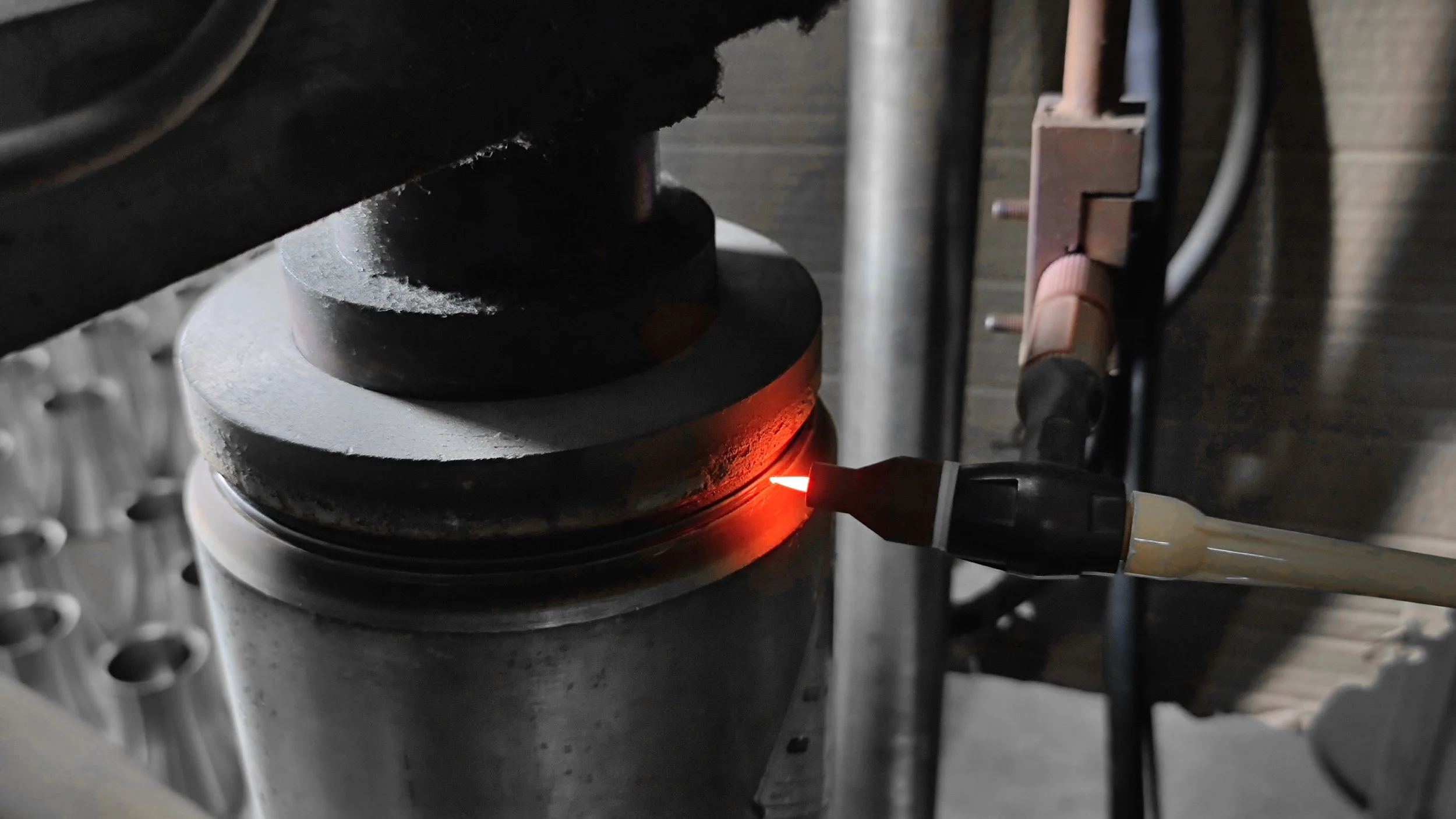

Ammonia Annealing Line

Our ammonia annealing line is designed for environmental protection, high thermal efficiency, and uniform heat treatment. It plays a critical role in:

Enhancing material strength and durability

Ensuring consistent surface finish and workability

Supporting sustainable, energy-conscious operations

This process is essential for producing high-quality stainless steel products with excellent formability and corrosion resistance — all while meeting modern environmental standards.

Welding & Cutting Department

Our welding department is equipped to handle a wide range of joining processes with precision, strength, and clean aesthetics — essential for both functional and consumer-facing hardware products.

2 Laser Cutting Machines

High-speed, high-precision metal cutting for intricate shapes and clean edges with minimal heat distortion.

4 Laser Welding Machines

Ideal for fine, high-strength welds on stainless steel and delicate components — ensuring minimal deformation and a clean finish.

4 Argon Arc (TIG) Welding Machines

Precision welding for complex assemblies and visible joints, delivering strong and refined connections.

8 Spot Welding Machines

Fast, reliable welds for sheet metal fabrication and subassembly components — perfect for high-volume production.

Our combination of manual and automated welding solutions allows us to support everything from prototype development to full-scale production while maintaining structural integrity and visual quality.

Polishing Department

At Songson, surface finishing is treated as a key part of product quality — especially for kitchenware and consumer goods where appearance and hygiene matter.

20 Manual Polishing Machines

Operated by experienced technicians for detailed surface finishing, custom textures, and precise visual control.

2 Automatic Polishing Machines

Ensure high-speed, consistent exterior surface treatment — ideal for large-volume production with uniform results.

4 Automatic Inner Polishing Machines

Specialized equipment designed to polish internal surfaces — critical for food-contact products such as kettles, mugs, and canisters.

Our polishing department combines manual craftsmanship with automation to achieve flawless finishes, whether it’s mirror-like shine, satin brush, or functional texture — helping elevate the final look and feel of every product.